Products

All Products

GLG Series-GLG Series - GLG-610

GLG-610 Download

| TRAVEL | ||

| X-axis | 610(24") | mm/(inch) |

| Y-axis | 460(18.1") | mm/(inch) |

| Z-axis | 480(18.8") | mm/(inch) |

| Spindle nose to table surface | 100-580 (3.9"-22.8") | mm/(inch) |

| Spindle center to column surface | 500(19.6") | mm/(inch) |

| X.Y.Z. Axis Ball screws dia | 32/12 Pitch-16mm(opt) | mm/(inch) |

| TABLE | ||

| Table Size | 700x 460 (27.5" x 18.1") | mm/(inch) |

| Working Area | 610x 460 (24" x 18.1") | mm/(inch) |

| Tee slots (CD x W x NO) | CD100 x 18 x 3 | mm/(inch) |

| Table load (maximun) | 300(660) | KG(Ibs) |

Specifications

- Machine characteristics

- video

- Specification Table

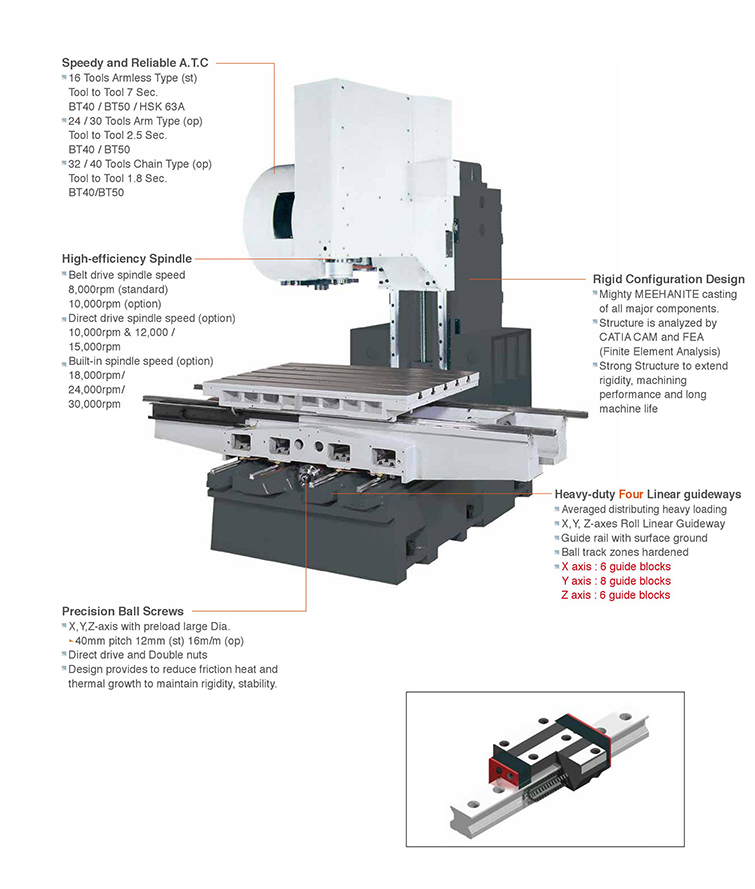

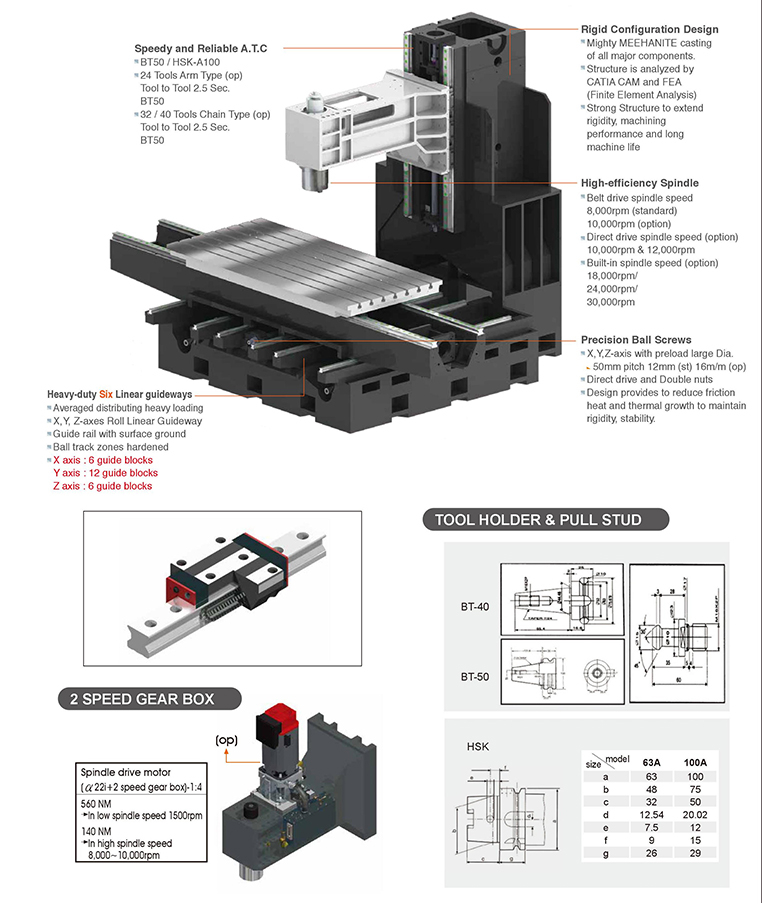

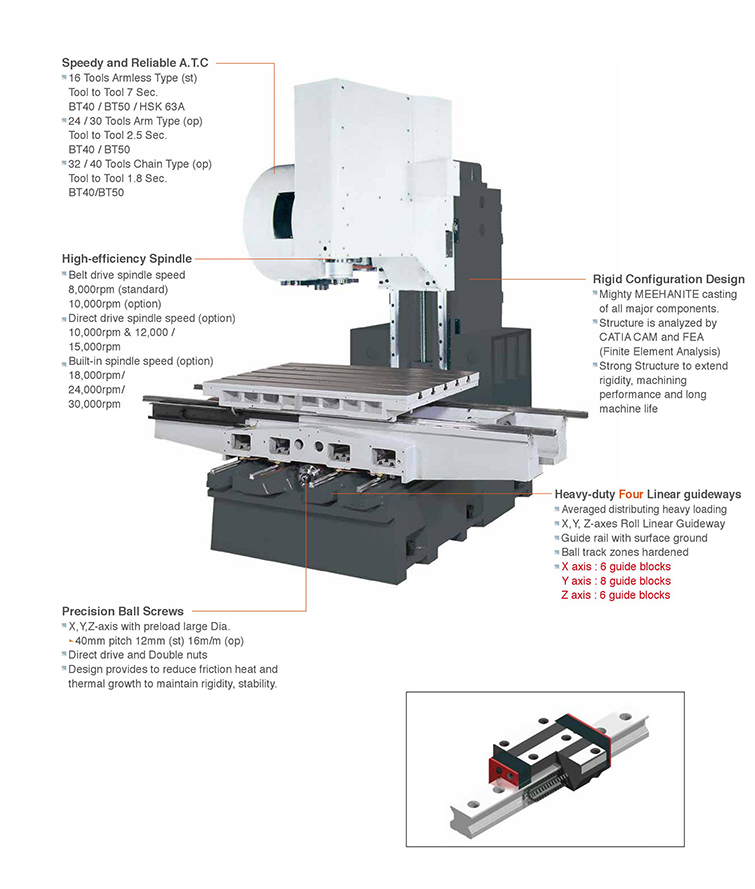

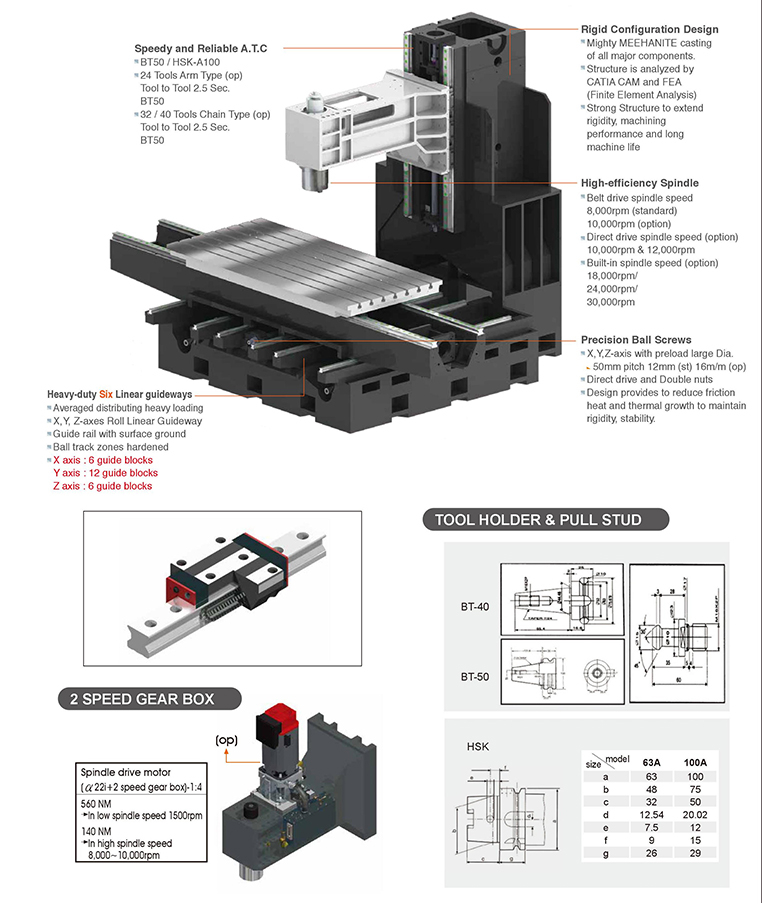

1 X,Y,Z-Axis linear roller guides for heavy loading

2. X travel over 1600mm, the base with 6 linear roller guides

3.Screw Type Chip Conveyor+Water Tank (Front)

Screw Type Automatic Chip Conveyor-2Pcs (Beside Y axis)

4. Spindle Cooling System

5. Functions of two water (oil) pumps :

one is for ① pressing chip flushing ② spindle splash ring ③ cutting coolant device: nozzle*2pcs and water gun

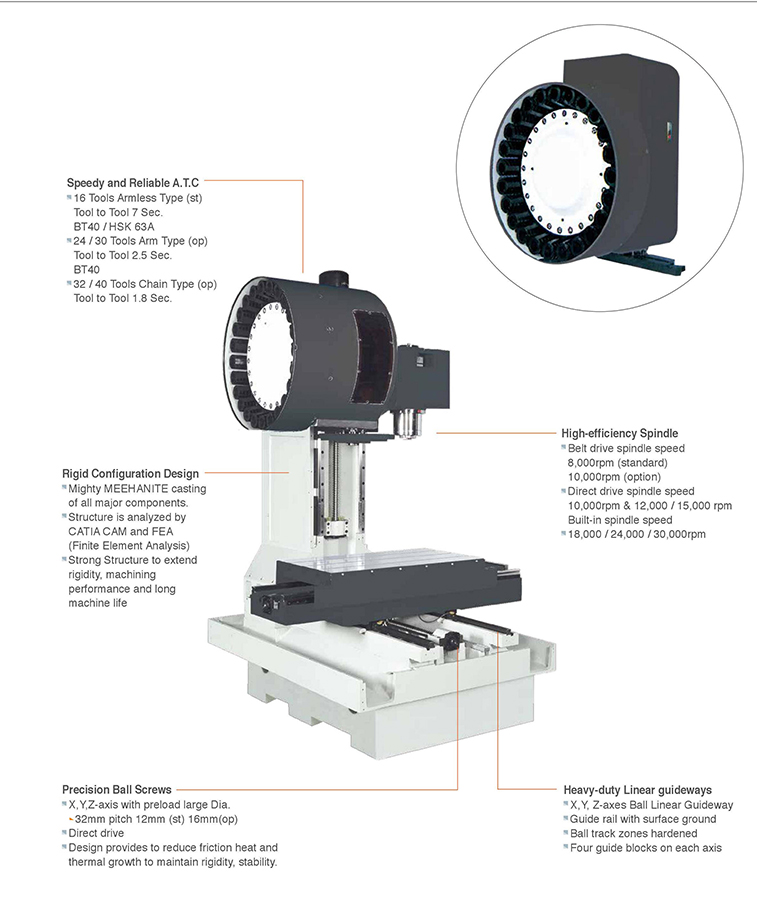

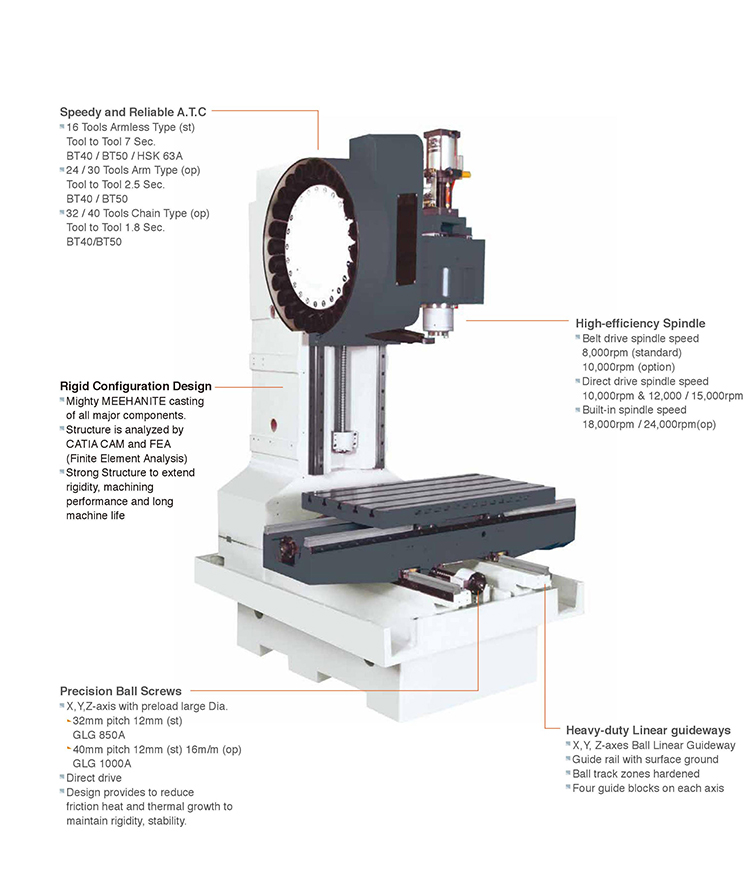

Structure

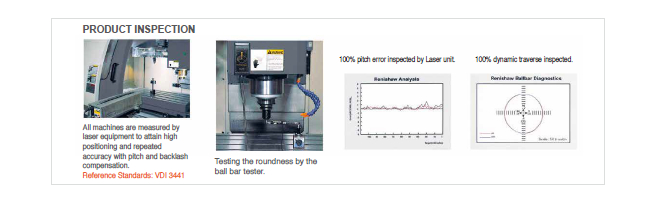

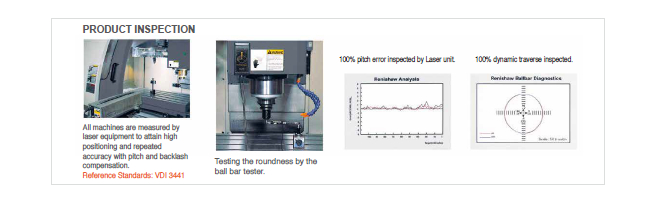

Quality

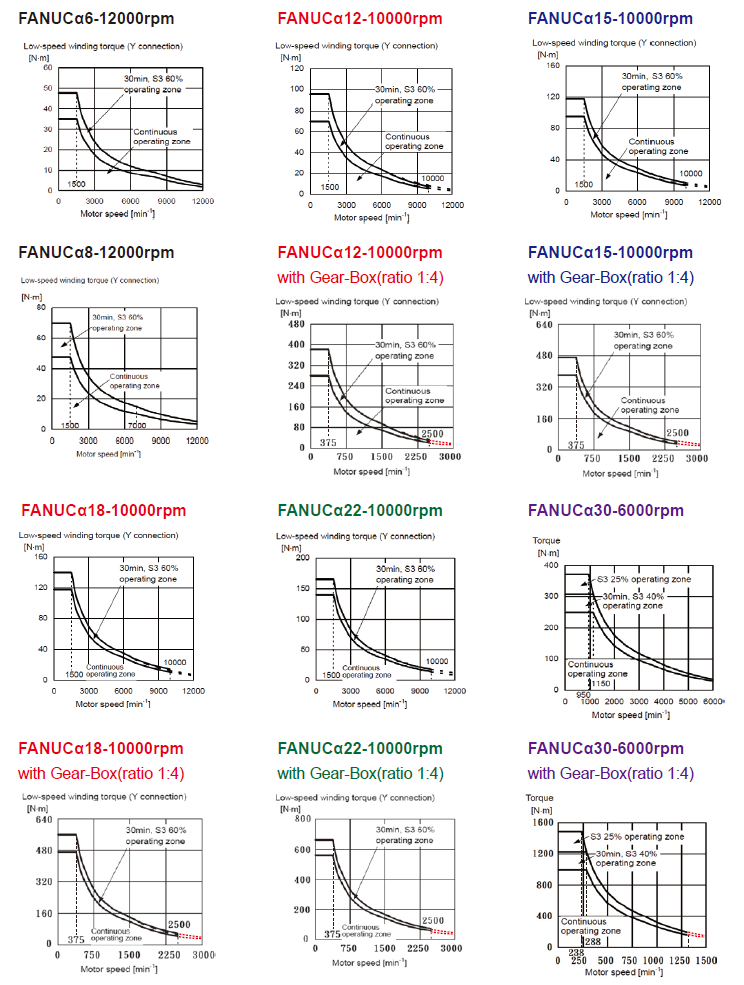

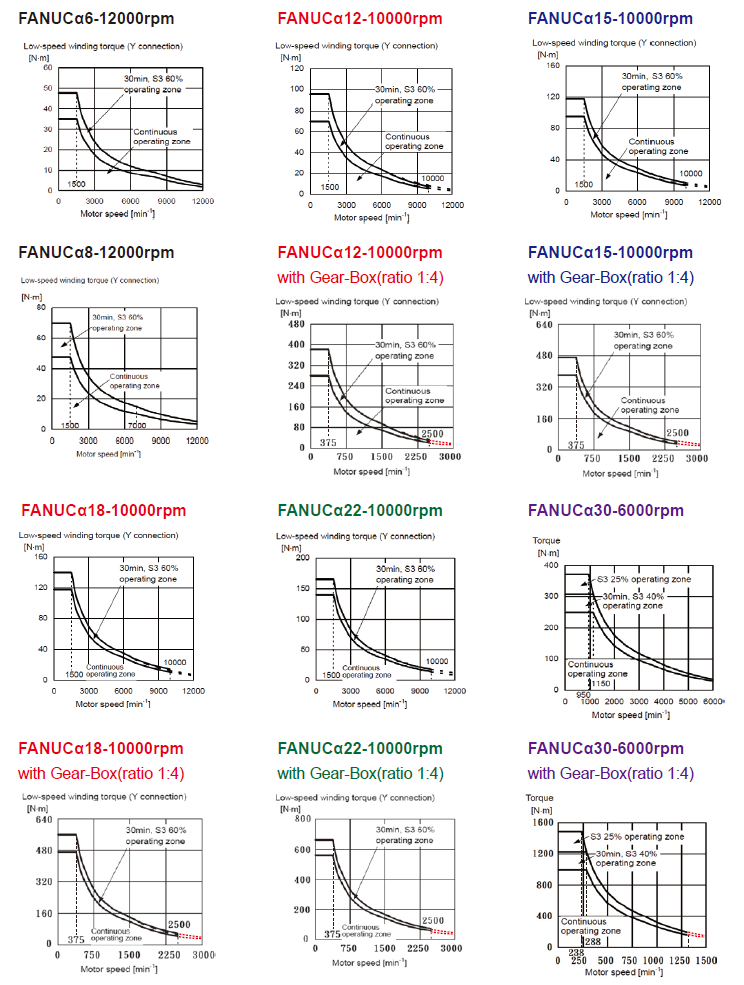

Spindel Torque

2. X travel over 1600mm, the base with 6 linear roller guides

3.Screw Type Chip Conveyor+Water Tank (Front)

Screw Type Automatic Chip Conveyor-2Pcs (Beside Y axis)

4. Spindle Cooling System

5. Functions of two water (oil) pumps :

one is for ① pressing chip flushing ② spindle splash ring ③ cutting coolant device: nozzle*2pcs and water gun

Structure

Quality

Spindel Torque

[Download]

*All specifications and designs are subject to change without notice.

| TRAVEL | ||

| X-axis | 610(24") | mm/(inch) |

| Y-axis | 460(18.1") | mm/(inch) |

| Z-axis | 480(18.8") | mm/(inch) |

| Spindle nose to table surface | 100-580 (3.9"-22.8") | mm/(inch) |

| Spindle center to column surface | 500(19.6") | mm/(inch) |

| X.Y.Z. Axis Ball screws dia | 32/12 Pitch-16mm(opt) | mm/(inch) |

| TABLE | ||

| Table Size | 700x 460 (27.5" x 18.1") | mm/(inch) |

| Working Area | 610x 460 (24" x 18.1") | mm/(inch) |

| Tee slots (CD x W x NO) | CD100 x 18 x 3 | mm/(inch) |

| Table load (maximun) | 300(660) | KG(Ibs) |

| SPINDLE | ||

| Spindle tapper | BT30 / BT40 | |

| Spindle speed - standard access | BT30 / 12,000 / opt 15,000 (Belt drive) Direct drive 15,000/20,000 rpm | RPM |

| Compatible with various types of spindels - Belt drive |

BT40 8,000 / 10,000 / 12,000 BT50 8,000 / 10,000 |

RPM |

| Compatible with various types of spindels - Direct drive Spindle |

opt BT40 10,000/12,000/15,000-Direct drive BT50 10,000/12,000-Direct drive | RPM |

| Compatible with various types of spindels - Built-in drive Spindle |

opt BT40 16,000/20,000/24,000/30,000-Built in BT 50 12,000/15,000/20,000 – Built in | RPM |

| FEEDRATE | ||

| Cutting Feedrate (X, Y, Z axis) | 1-10000(Depending Controller) | MM/MIN |

| 3Axes Slideways | LINEAR BALL SLIDE | |

| Rapid Traverse Rates (X/Y/Z axis) | 30/30/24 / opt 48/48/24 | MM/MIN |

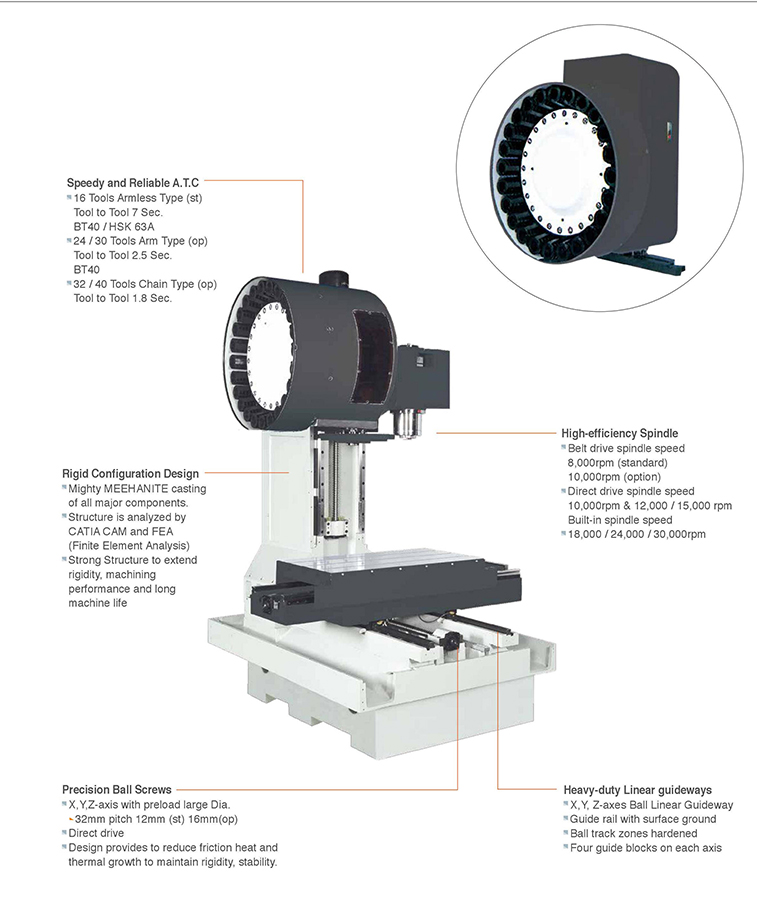

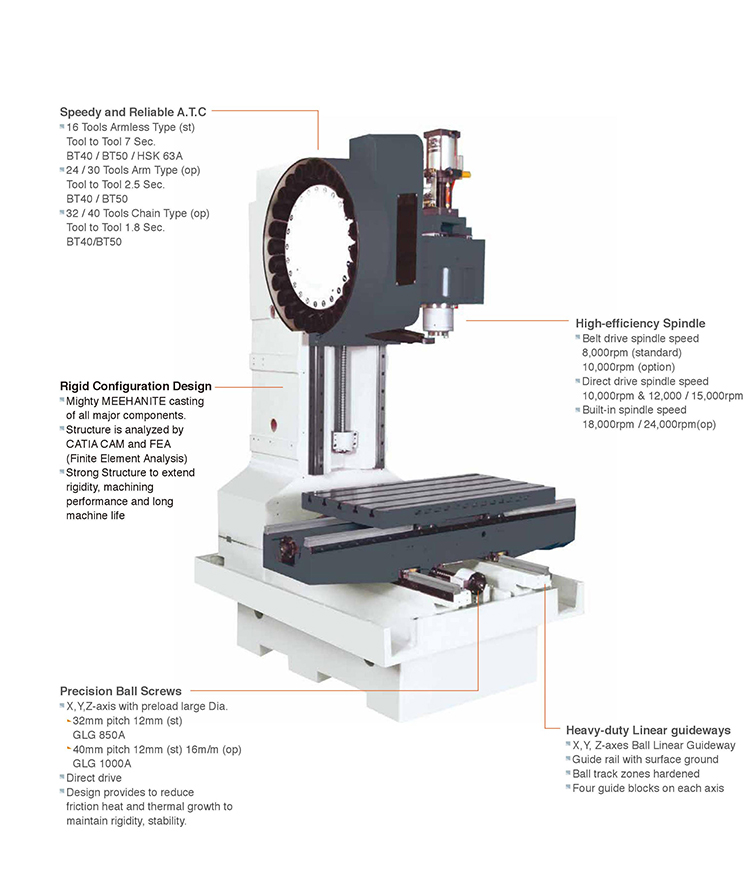

| ATC | ||

| Capacity-standard access. | 16(Armless) | PCS |

| Capacity-optional access.(ARM) | 24/30(Arm), 32/40(Chain Type) | PCS |

| Tool Selection | Bi-directional & min.path | |

| Maximum tool diameter x length | Armless: 80 x 250 (3.1"x9.8") | MM(inch) |

| Maximum tool weight | Armless6(13.2) / Arm 8(17.6) | KG(lbs) |

| Air Power required | 6kg / cm2 | |

| Tool Shank | BT30/ISO30/BT40/ISO40/CAT40 | |

| MOTOR | ||

| Spindle drive Motor | Std: 5.5/7.58KW 7.5HP | KW(HP) |

| LINEAR BALL SLIDE | ||

| X/Y/Z axis | 25x2sets / 30x2sets/30x2sets | |

| Carriage guide block-per axis | 4 / 4 / 4 blocks | |

| Coolant Pump | 1/2 | HP |

| Power Supply | 15KVA | |

| NET WEIGHT | 3500(7700) | KG(lbs) |

| SIZE | ||

| A | 260 | cm |

| B | 190 | cm |

| C | 180 | cm |

| D | 80 | cm |

| E | 272/282 | cm |