Products

All Products

DMC Series-18 Series - DMC-3018

DMC-3018 Download

| Travel | ||

| X-axis | 3000(118") | mm/(inch) |

| Y-axis | 1700(67") | mm/(inch) |

| Z-axis | 900(35.4") | mm/(inch) |

| Z axis(O.P.) | mm/(inch) | |

| Spindle nose to table surface | 120~1020(4.7~40.1") | mm/(inch) |

| Distance between columns | 1800/70.8 | mm/(inch) |

| Table Dimension | 3200 x 1700(125.9 x 67") | mm/(inch) |

| Spindle speed (Built-in type) | 18,000/20,000(O.P.) | RPM |

| Spindle motor (Built-in type) / Torque Max. | 21kw / 200NM | kw/NM |

Specifications

- Machine characteristics

- video

- Specification Table

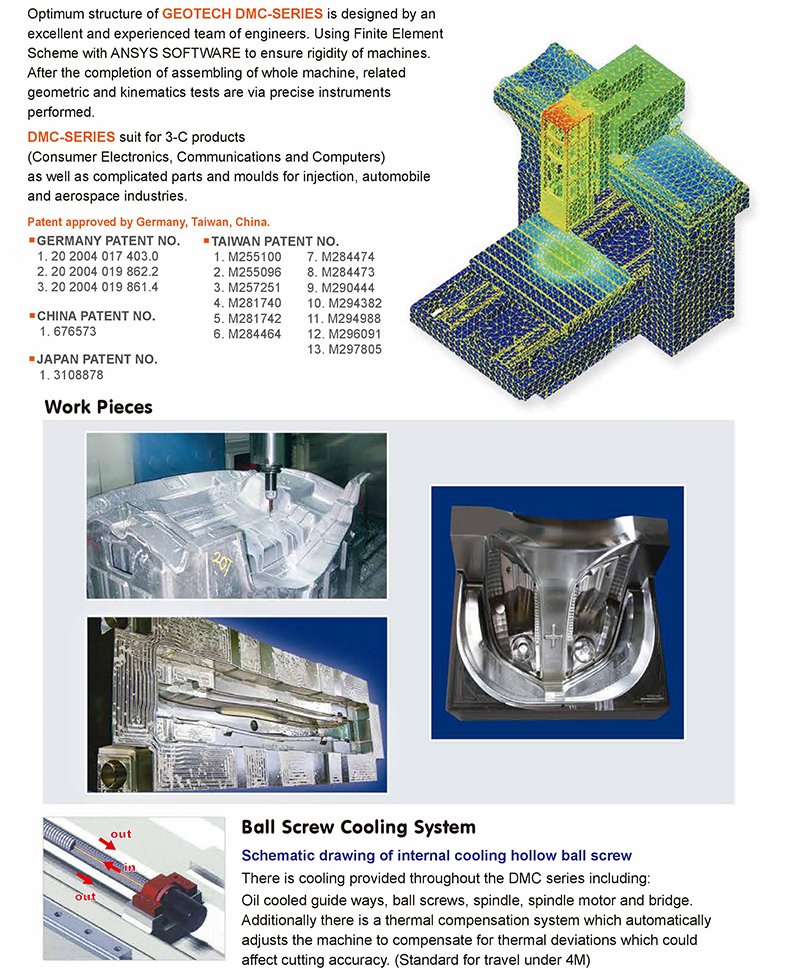

SPECIFICATION & FEATURES FOR DOUBLE COLUMN MACHINING CENTER

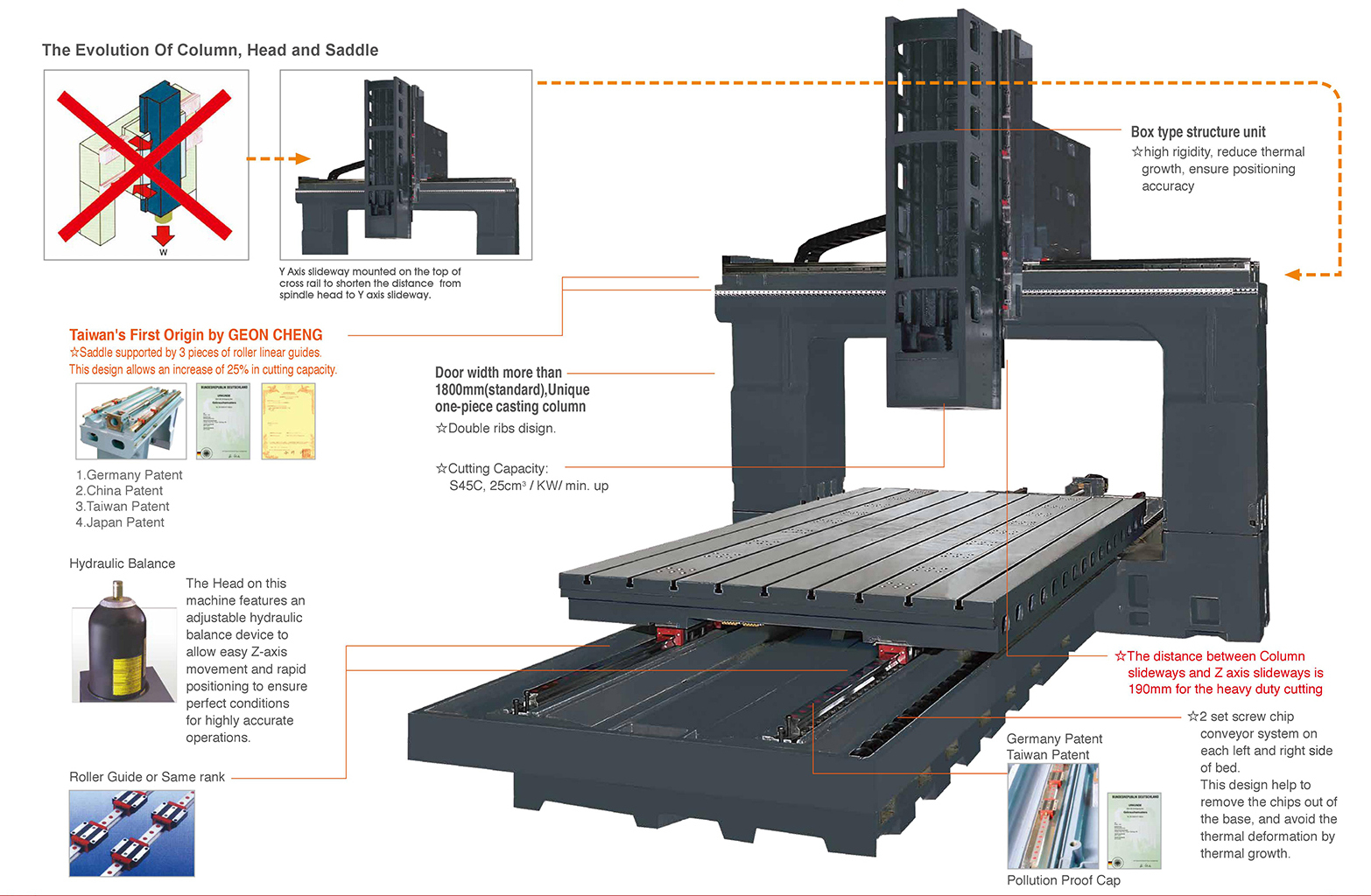

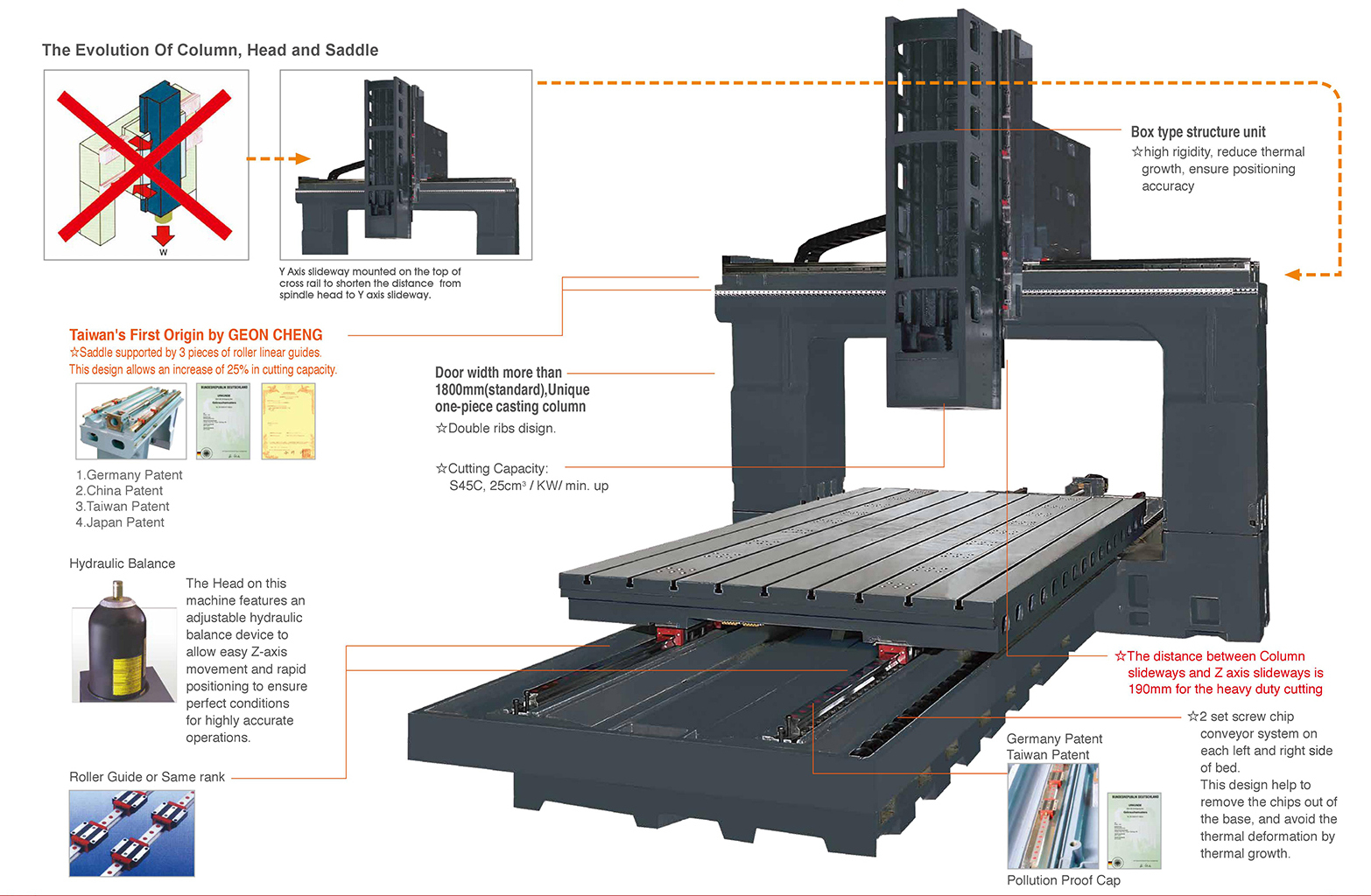

1. 3 axes with Linear Guide ways - roller type provide with overall rigidity.

2.Oil Cooling System for X.Y Axes Ballscrew.

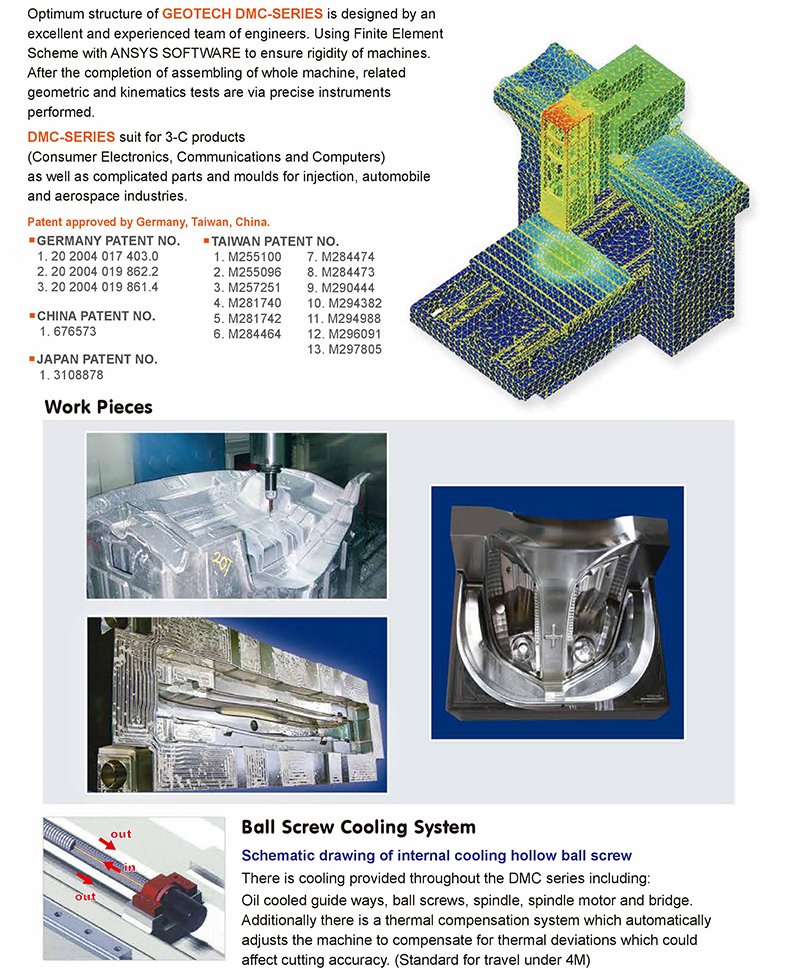

3.Patent No. 202004017403.0 was granted by Germany and 1059432 was granted by Spain for improvements in Y-axis (saddle) with three pieces of linear guide ways. The machining rate is increased by 25%.

4.Z-axis (Head) with 4 pieces of Linear Guide ways enabling more stability while cutting.

5.Screw Chip Conveyor system on both sides of bed (X-axis), to help to remove chips out of the bed, avoiding thermal growth.

6.Patent No. 202004019862.2 and 202004019861.4 were granted by Germany for improvements on the radial ribbing design to absorb both the radial and axial forces to achieve rigid machine.

7.Patent No. 202004019861.4 were granted by Germany for improvements on pollution-preventive mechanism on the bed.

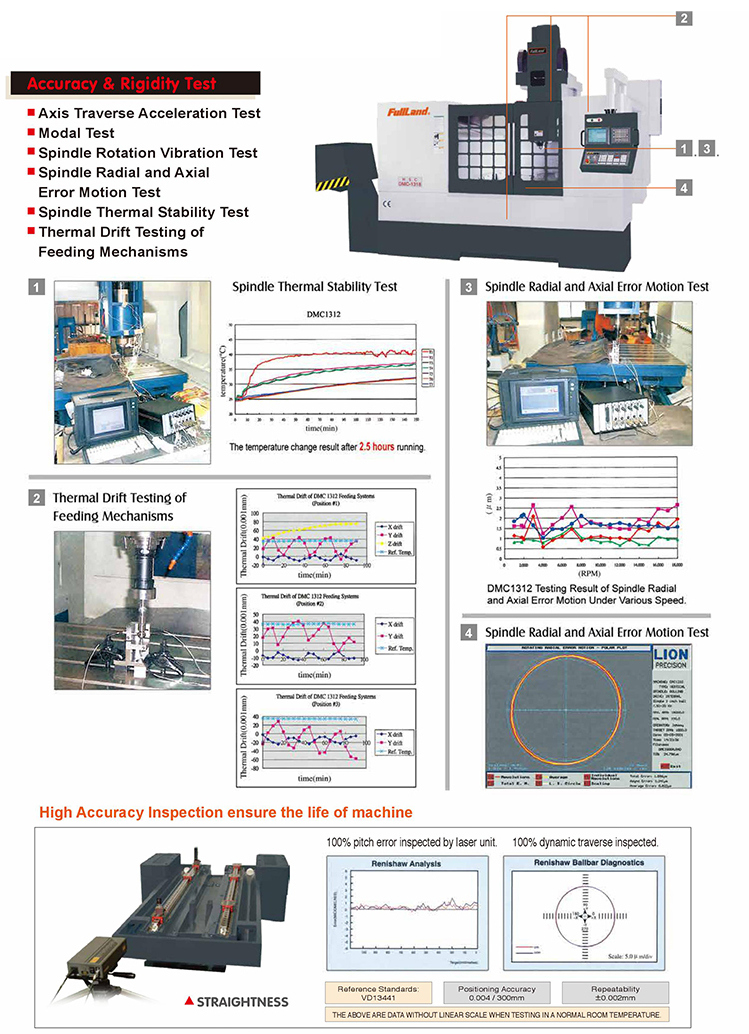

Structure

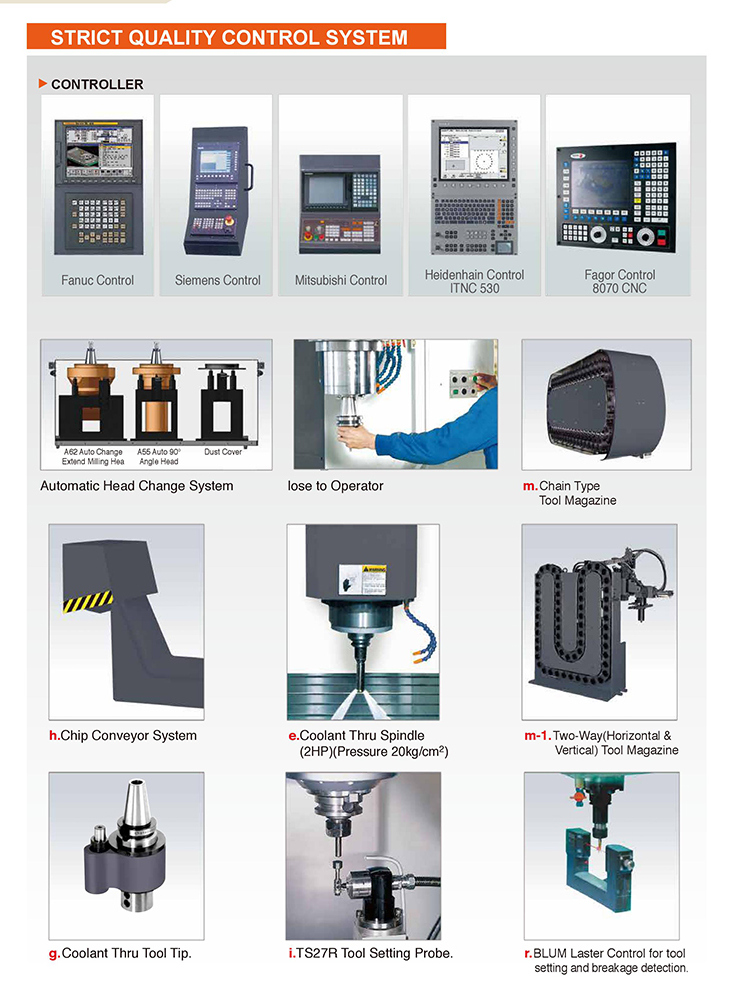

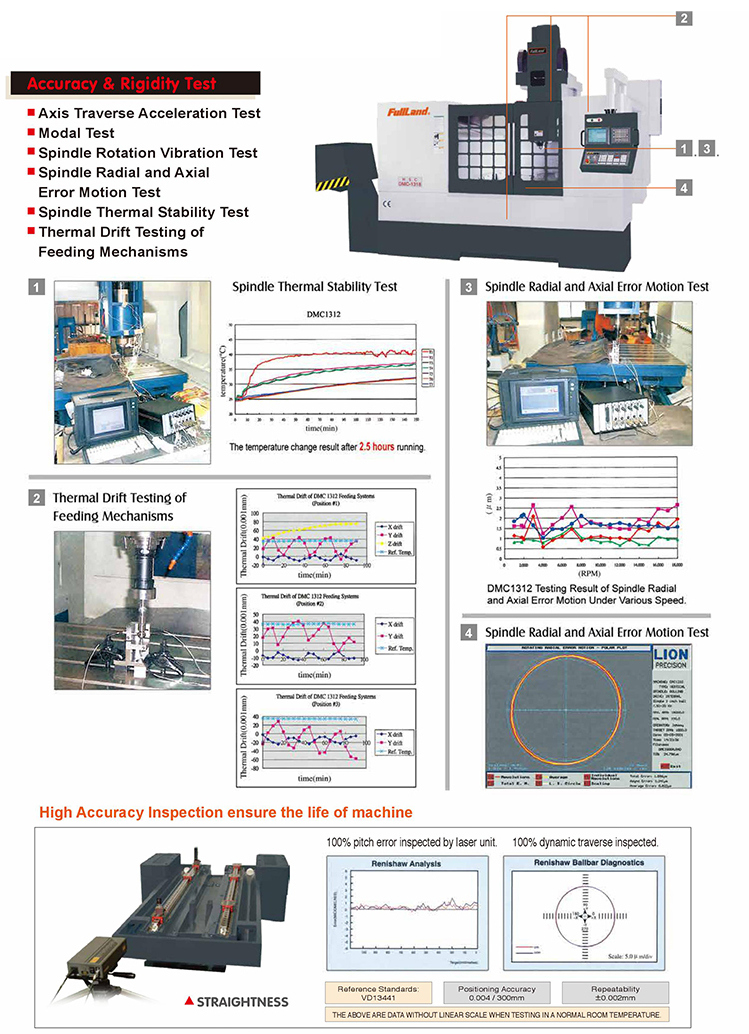

Quality

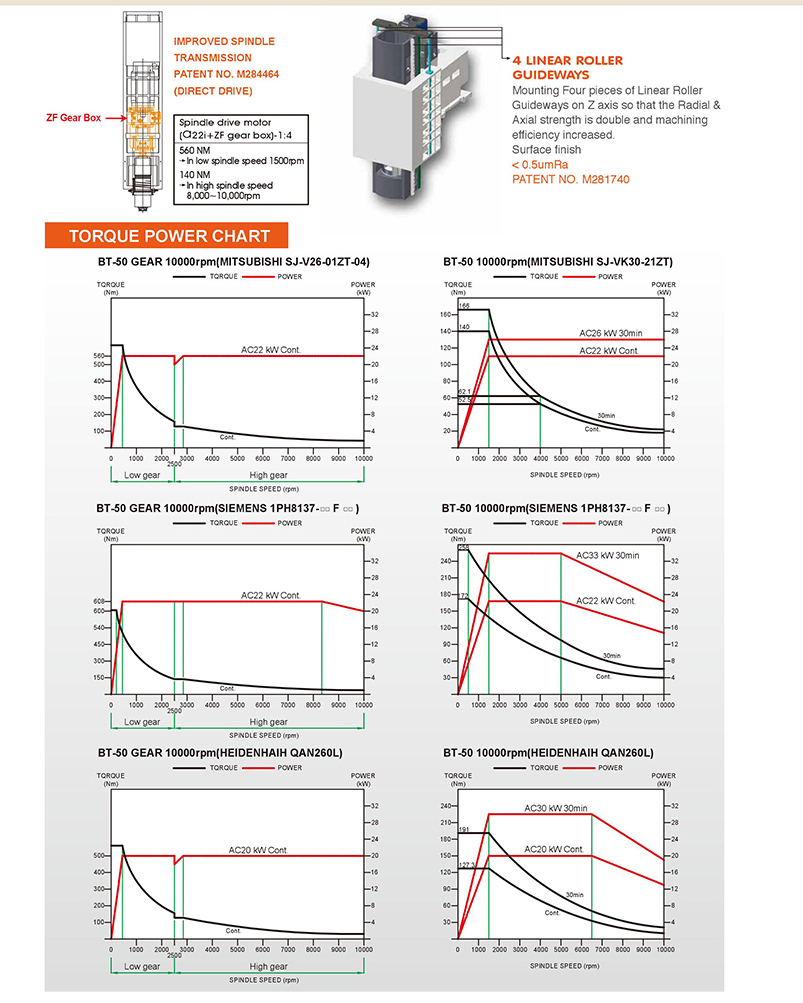

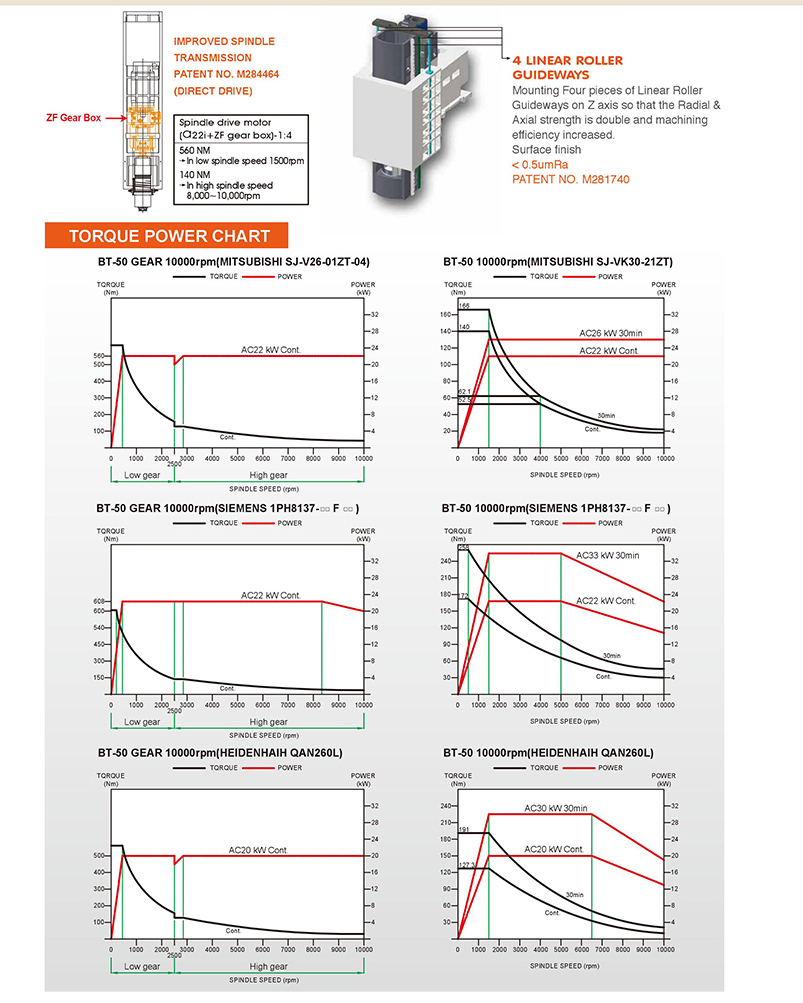

Spindel Torque

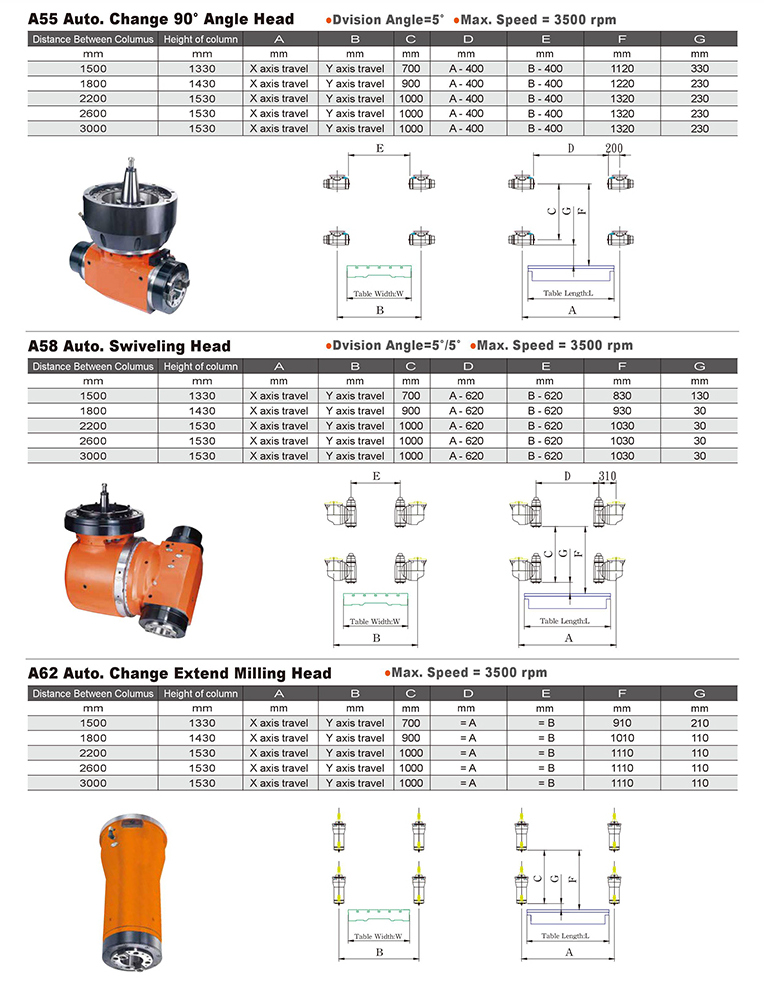

Change Head System

Control system &Options

1. 3 axes with Linear Guide ways - roller type provide with overall rigidity.

2.Oil Cooling System for X.Y Axes Ballscrew.

3.Patent No. 202004017403.0 was granted by Germany and 1059432 was granted by Spain for improvements in Y-axis (saddle) with three pieces of linear guide ways. The machining rate is increased by 25%.

4.Z-axis (Head) with 4 pieces of Linear Guide ways enabling more stability while cutting.

5.Screw Chip Conveyor system on both sides of bed (X-axis), to help to remove chips out of the bed, avoiding thermal growth.

6.Patent No. 202004019862.2 and 202004019861.4 were granted by Germany for improvements on the radial ribbing design to absorb both the radial and axial forces to achieve rigid machine.

7.Patent No. 202004019861.4 were granted by Germany for improvements on pollution-preventive mechanism on the bed.

Structure

Quality

Spindel Torque

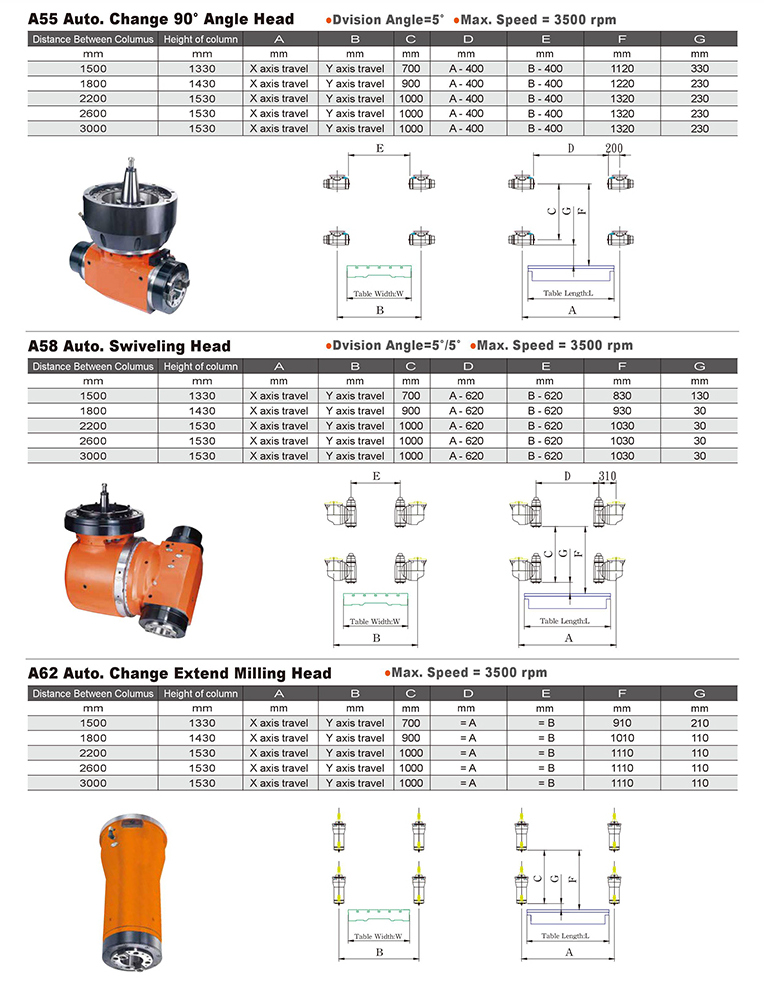

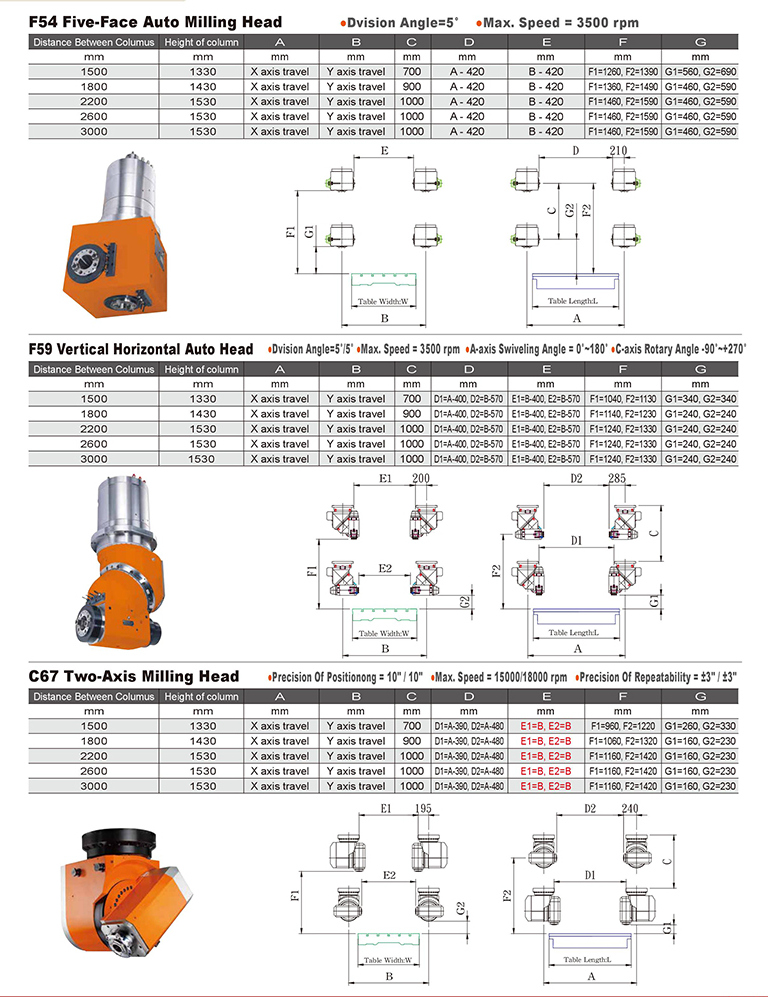

Change Head System

Control system &Options

[Download]

*All specifications and designs are subject to change without notice.

| Travel | ||

| X-axis | 3000(118") | mm/(inch) |

| Y-axis | 1700(67") | mm/(inch) |

| Z-axis | 900(35.4") | mm/(inch) |

| Z axis(O.P.) | mm/(inch) | |

| Spindle nose to table surface | 120~1020(4.7~40.1") | mm/(inch) |

| Distance between columns | 1800/70.8 | mm/(inch) |

| Table | ||

| Dimension | 3200 x 1700(125.9 x 67") | mm/(inch) |

| Working area | 3000 x 1660(118 x 61.4") | mm/(inch) |

| T-Slot (W x No. x CD) | 22 x 9 x 200 | mm/(inch) |

| Max. Table load | 6200/13640 | KG(Ibs) |

| Spindle | ||

| Spindle speed (Built-in type) | 18,000/20,000(O.P.) | RPM |

| Spindle motor (Built-in type) / Torque Max. | 21kw / 200NM | kw/NM |

| Spindle Taper | HSK 63A | |

| Spindle speed (Direct Drive) | BT40: 12,000 / 15,000 BT50:8,000/10,000/12,000rpm(O.P.) |

RPM |

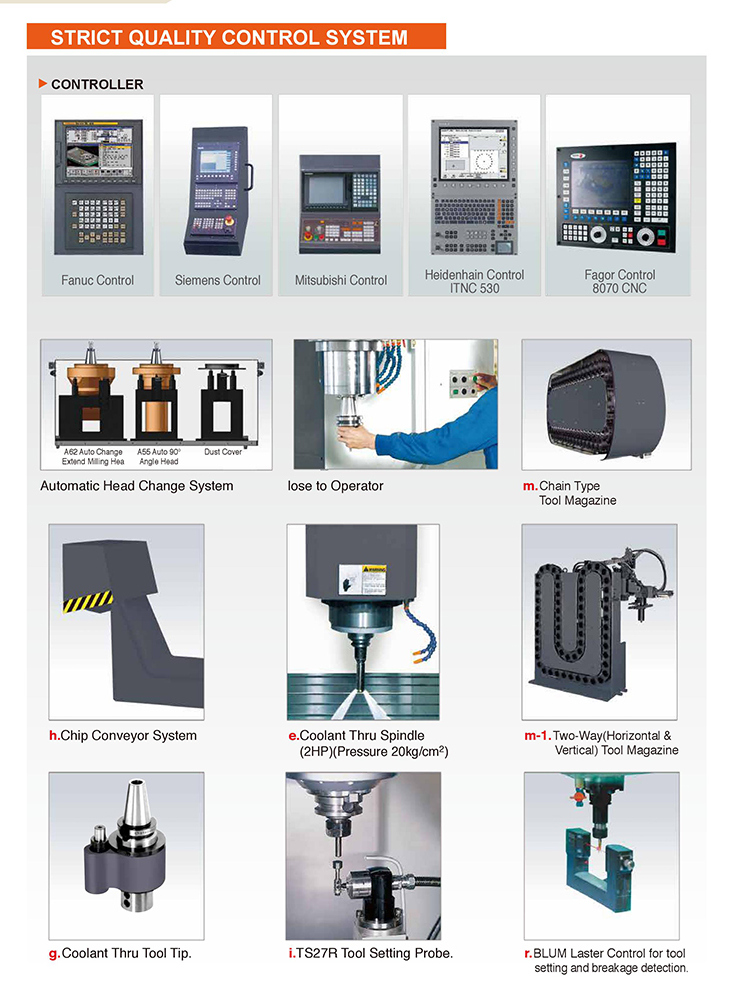

| Controller | Fanuc/Mitsubishi/Siemens | |

| Dual-speed spindle motor Kw-Nm(L/H) (Direct Drive) | 1.Fanuc- ①αT8 / ②αT15 / ③αL15/④ αL26 / ⑤ αB160LL / ⑥ αL8 ① αT8 7.5Kw-15000rpm L:47Nm H:23.9Nm ② αT15 18.5Kw-12000rpm L:102Nm H:28.6Nm ③ αL15 18.5Kw-15000rpm L:150Nm H:35Nm ④ αL26 (18.5-22kw) 10000rpm L:286Nm H:88Nm ⑤ αB160LL (30kw) 10000rpm L:350Nm H:95Nm ⑥ αL8 11-15Kw-20000rpm L:79.5Nm H:23.9Nm ---------------------------------------------- 2.Mitsubishi- SJ-VKRS30-06ZM 22Kw-10000rpm L:286Nm H:88Nm ---------------------------------------------- 3.Siemens- 1PM6138-2LF8 22Kw-10000rpm L:140Nm H:53Nm |

Kw/Nm |

| α22+ZF Gear Box α30+ZF(Direct Drive) | (After Mounting Gear Box) H:8000rpm/140NM L:2000rpm/560NM |

(1:4) |

| SJ-V26+ZF Gear Box(Direct Drive) | (After Mounting Gear Box, the torque increase 4 times at low speed) H:8000rpm/286NM L:700rpm/1140NM |

(1:4) |

| Spindle Taper (o.p.) | BT50/DIN69871 | |

| Feedrate | ||

| Cutting feed | 1-10,000(DEPENDING ON CONTROLLER) | mm |

| X/Y axis rapid traverse(o.p.) | 16000 | mm |

| Z axis rapid traverse(o.p.) | 12000 | mm |

| X axis servo motor | 30 | NM |

| Y/Z axis servo motor | 22/30(Z axis Hydraulic Balance) | NM |

| Linear guide (Roller Type) | ||

| X/Y/Z axis | X:55x2sets/ Y:45x2sets 25x1set/ Z:55x2sets | mm |

| Ballscrew | ||

| X axis ballscrew dia x pitch | 55 x 16 | mm |

| Y axis ballscrew dia x pitch | 50 x 12 | mm |

| Z axis ballscrew dia x pitch | 45x10 | |

| A.T.C. | ||

| Type of tool(HSK63A/BT40) | Armless type | Armless |

| Tool capacity | 12(OP)16/20 | |

| Type of tool(for BT40/BT50) | Arm | Arm |

| Tool capacity | 24/30(Disc type) 32/40/60/80/120(Chain type) | |

| Maximum tool diameter | 24T(BT40) : 135 (5.3") 24T(BT50) : 160 (6.3") |

mm/inch |

| Maximum tool length | 24T(BT40) : 300 (11.8") 24T(BT50) : 400 (15.7") |

mm/inch |

| Maximum tool weight | 8 (17.63) / 20 (44) | kgs/lbs |

| Tool to tool time | 1.8 / 2.5 | Sec |

| Air supply | 6 | kg/cm2 |

| Power supply | 35 | KVA |

| Coolant pump | 1HP x 2pcs | HP |

| Machine weight (net) | 28,500/62,700 | kgs/lbs |

| Raiser block 200mm(O.P.) | ─ | mm |

| Raiser block 500mm(O.P.) | ─ | mm |