Products

All Products

DMC-5XH Series-22 Series - DMC-4022-5XH

DMC-4022-5XH Download

| TRAVEL | ||

| X axis | 4000 / 157.5˝ | mm/(inch) |

| Y axis | 2100 +480 / (82.6˝ +18.8˝) | mm/(inch) |

| Z axis | 1000 / 39.4˝ | mm/(inch) |

| Distance between columns | 2200 / 86.6˝ | mm/(inch) |

| Table size | 4200 x 1800 / (165.4˝x70.8˝) | mm/(inch) |

| Spindle speed (Built-in type) | 18000 RPM | rpm |

Specifications

- Machine characteristics

- video

- Specification Table

SPECIFICATION & FEATURES FOR DOUBLE COLUMN MACHINING CENTER

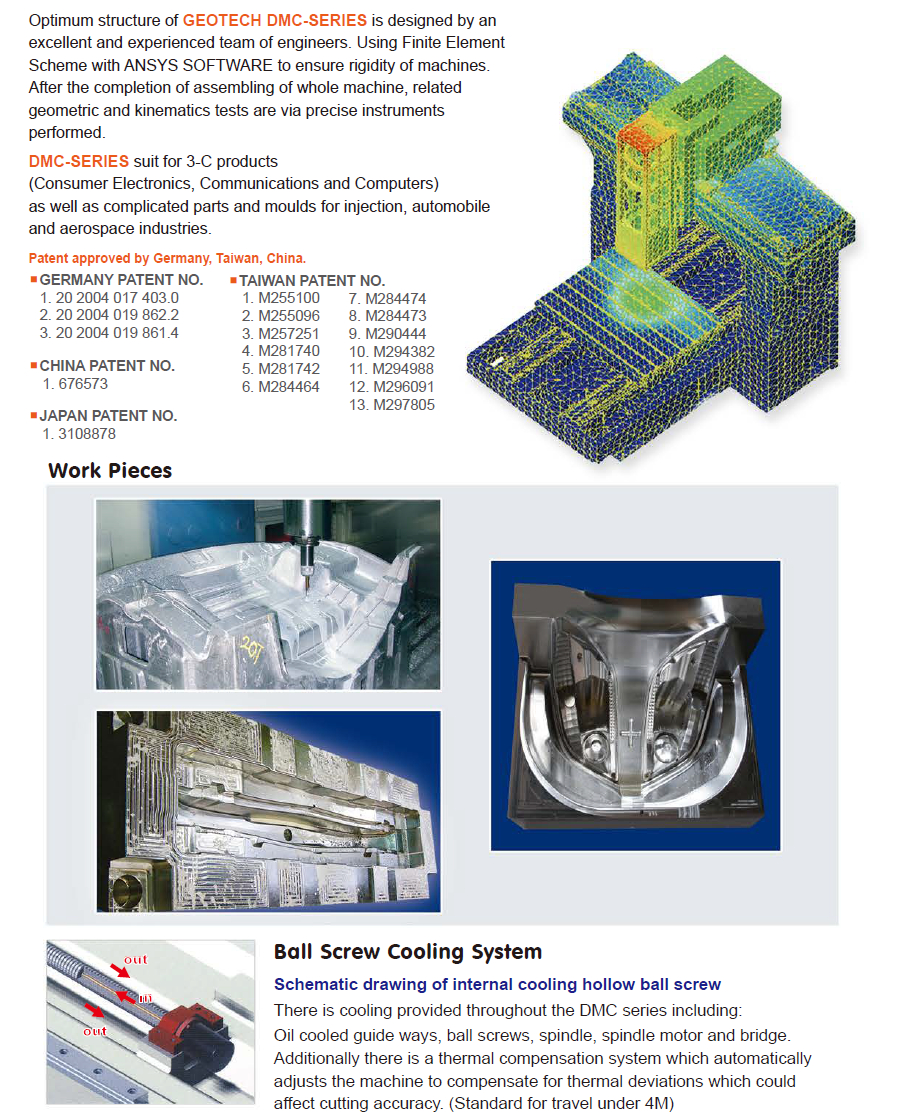

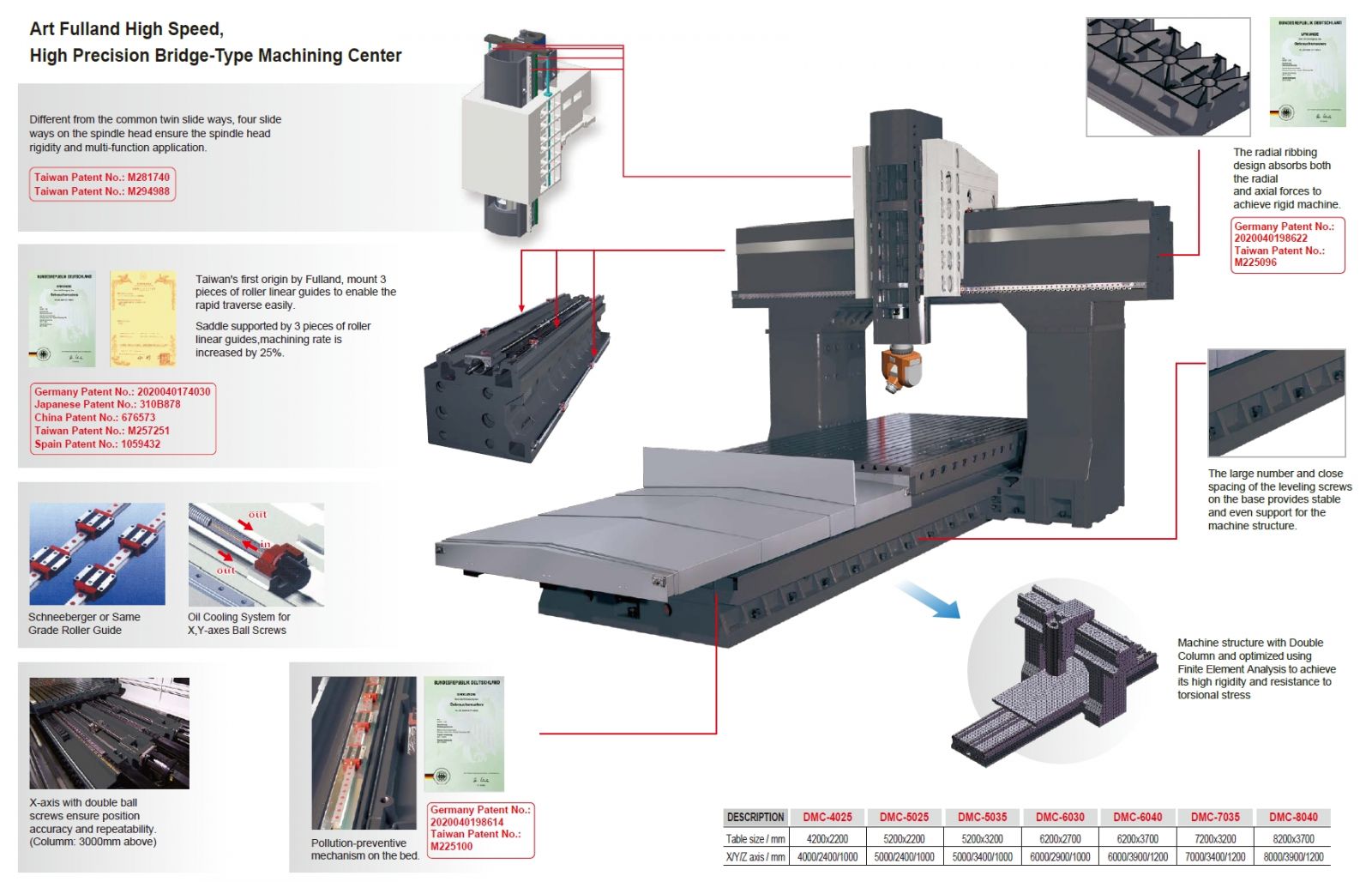

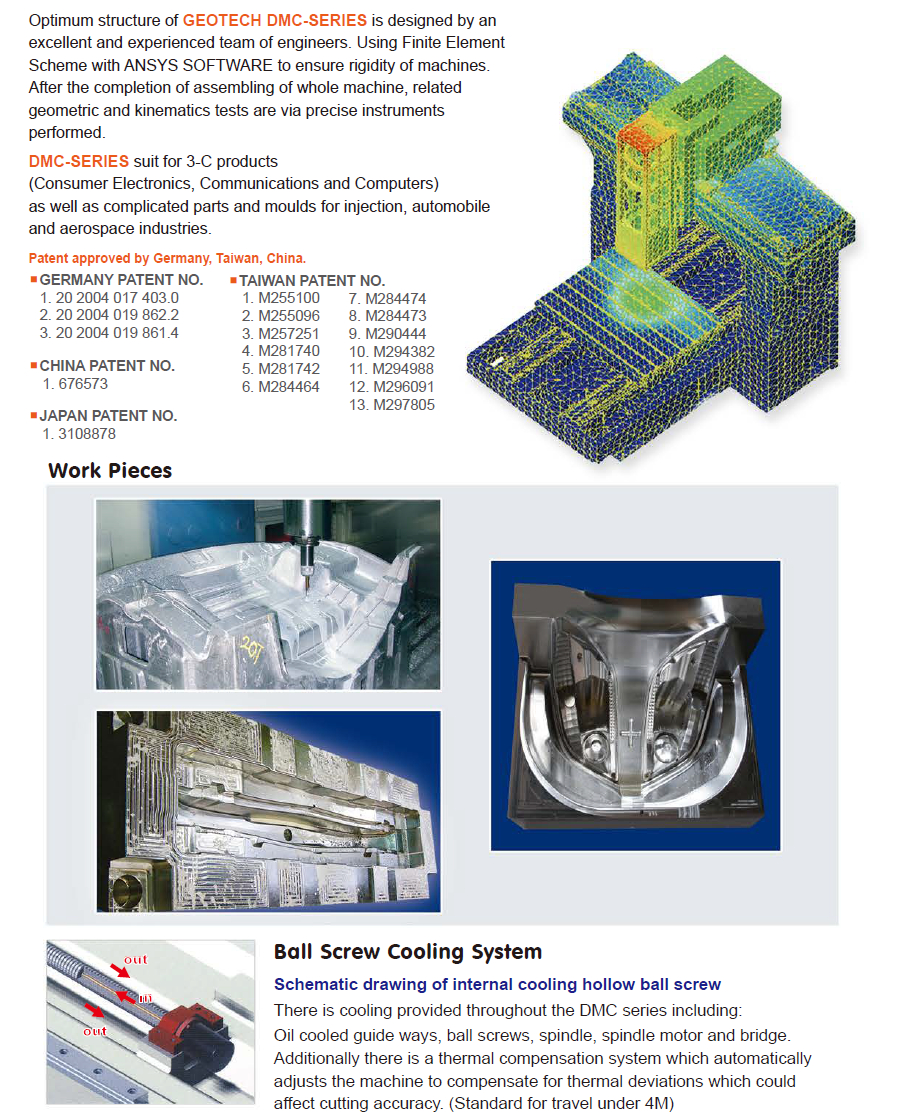

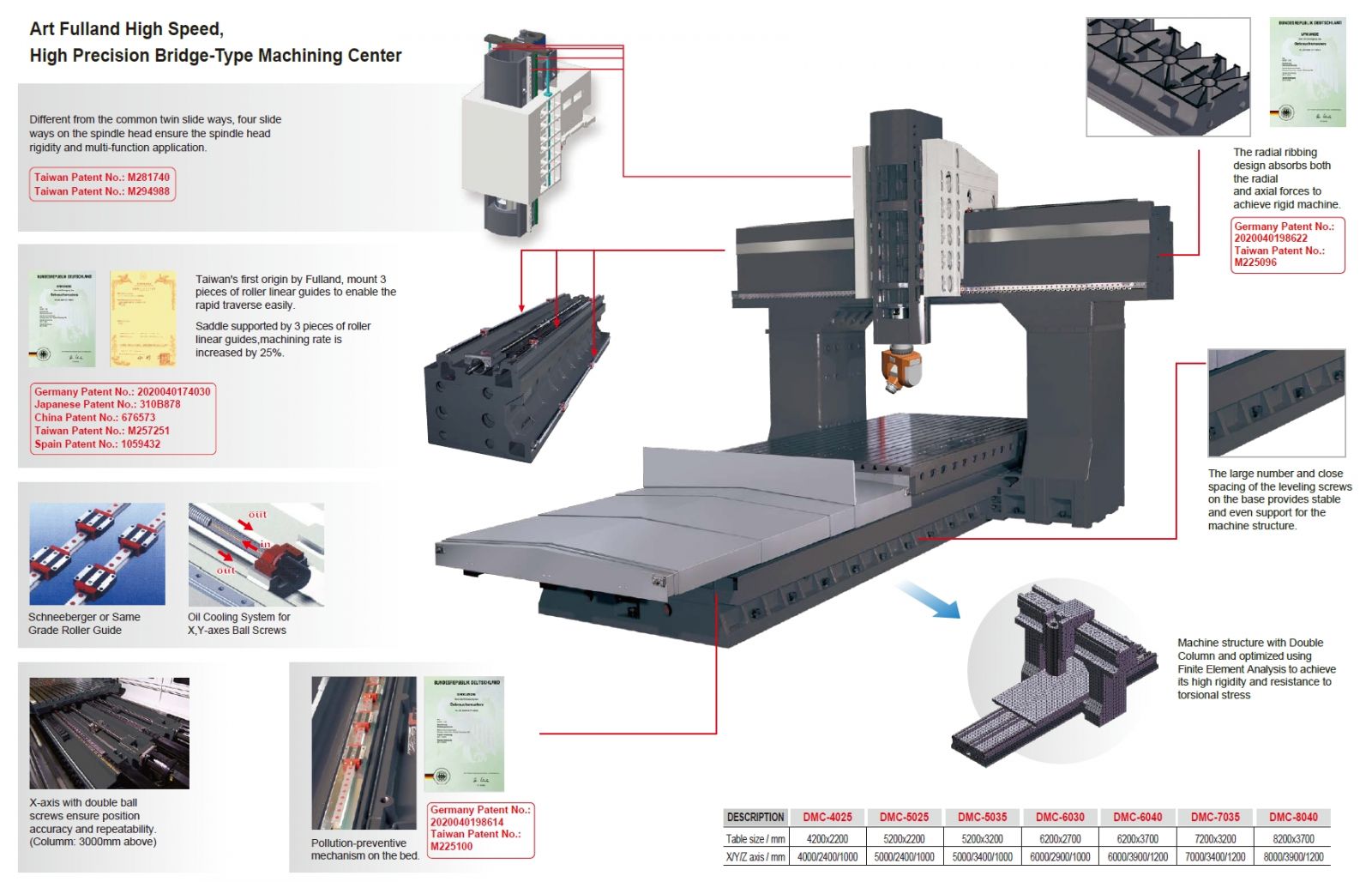

◎ 3 axes with Linear Guide ways - roller type provide with overall rigidity.

◎ Oil Cooling System for X.Y Axes Ballscrew.

◎ Patent No. 202004017403.0 was granted by Germany and 1059432 was granted by Spain for improvements in Y-axis (saddle) with three pieces of linear guide ways. The machining rate is increased by 25%.

◎ Z-axis (Head) with 4 pieces of Linear Guide ways enabling more stability while cutting.

◎ Screw Chip Conveyor system on both sides of bed (X-axis), to help to remove chips out of the bed, avoiding thermal growth.

◎ Patent No. 202004019862.2 and 202004019861.4 were granted by Germany for improvements on the radial ribbing design to absorb both the radial and axial forces to achieve rigid machine.

◎ Patent No. 202004019861.4 were granted by Germany for improvements on pollution-preventive mechanism on the bed.

Structure/

Quality

Spindel Torque

◎ 3 axes with Linear Guide ways - roller type provide with overall rigidity.

◎ Oil Cooling System for X.Y Axes Ballscrew.

◎ Patent No. 202004017403.0 was granted by Germany and 1059432 was granted by Spain for improvements in Y-axis (saddle) with three pieces of linear guide ways. The machining rate is increased by 25%.

◎ Z-axis (Head) with 4 pieces of Linear Guide ways enabling more stability while cutting.

◎ Screw Chip Conveyor system on both sides of bed (X-axis), to help to remove chips out of the bed, avoiding thermal growth.

◎ Patent No. 202004019862.2 and 202004019861.4 were granted by Germany for improvements on the radial ribbing design to absorb both the radial and axial forces to achieve rigid machine.

◎ Patent No. 202004019861.4 were granted by Germany for improvements on pollution-preventive mechanism on the bed.

Structure/

Quality

Spindel Torque

[Download]

*All specifications and designs are subject to change without notice.

| TRAVEL | ||

| X axis | 4000 / 157.5˝ | mm/(inch) |

| Y axis | 2100 +480 / (82.6˝ +18.8˝) | mm/(inch) |

| Z axis | 1000 / 39.4˝ | mm/(inch) |

| Distance between columns | 2200 / 86.6˝ | mm/(inch) |

| Table | ||

| Dimension | 4200 x 1800 / (165.4˝x70.8˝) | mm/(inch) |

| Working area (without tool length) | 3520 x 2100 / (138.5˝x82.6˝) | mm/inch |

| T-Slot (W x No. x CD) | 22 x 10 x 200 | mm |

| Max. Table load | 12000 / 26400 | kgs / lbs |

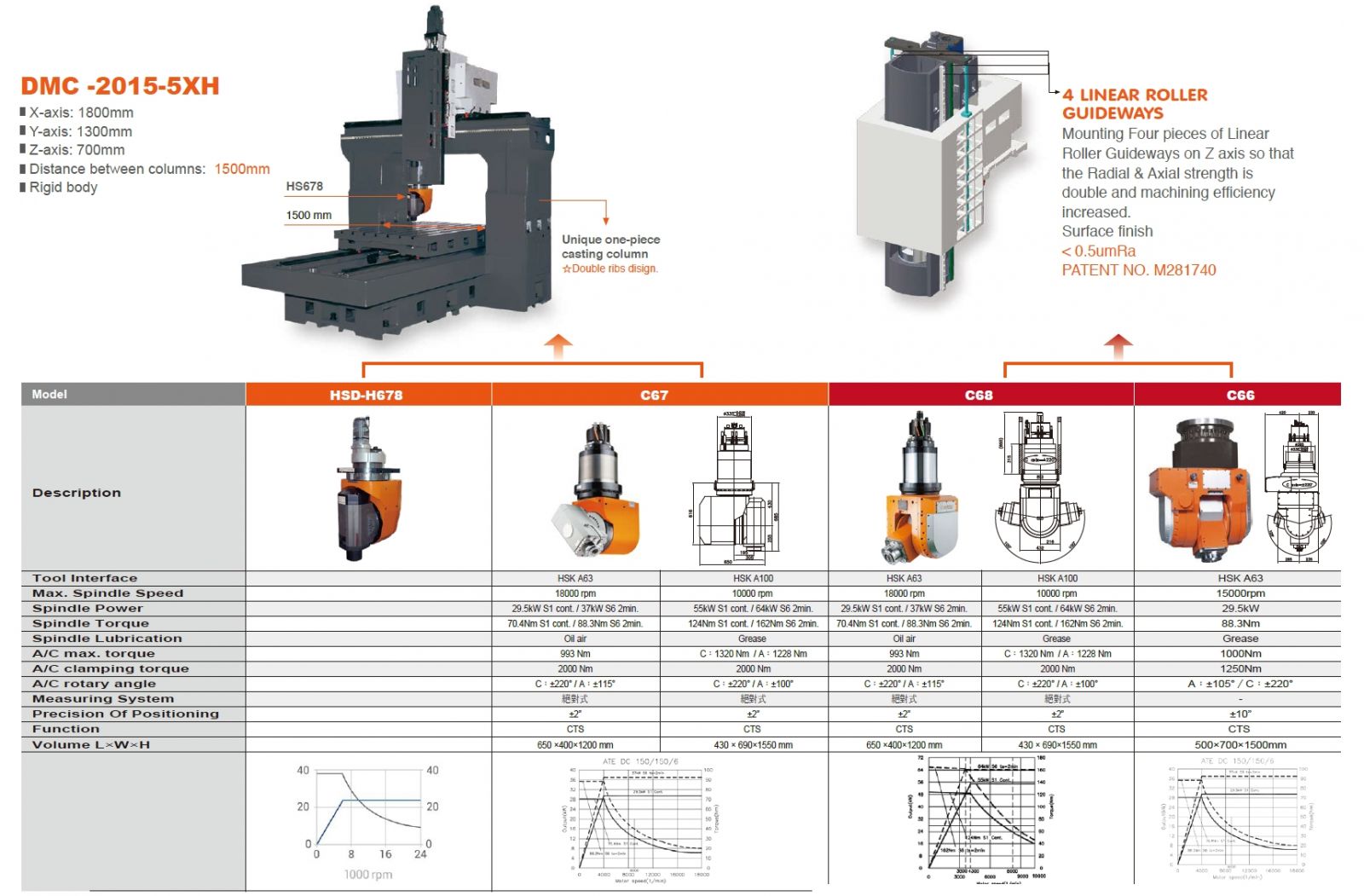

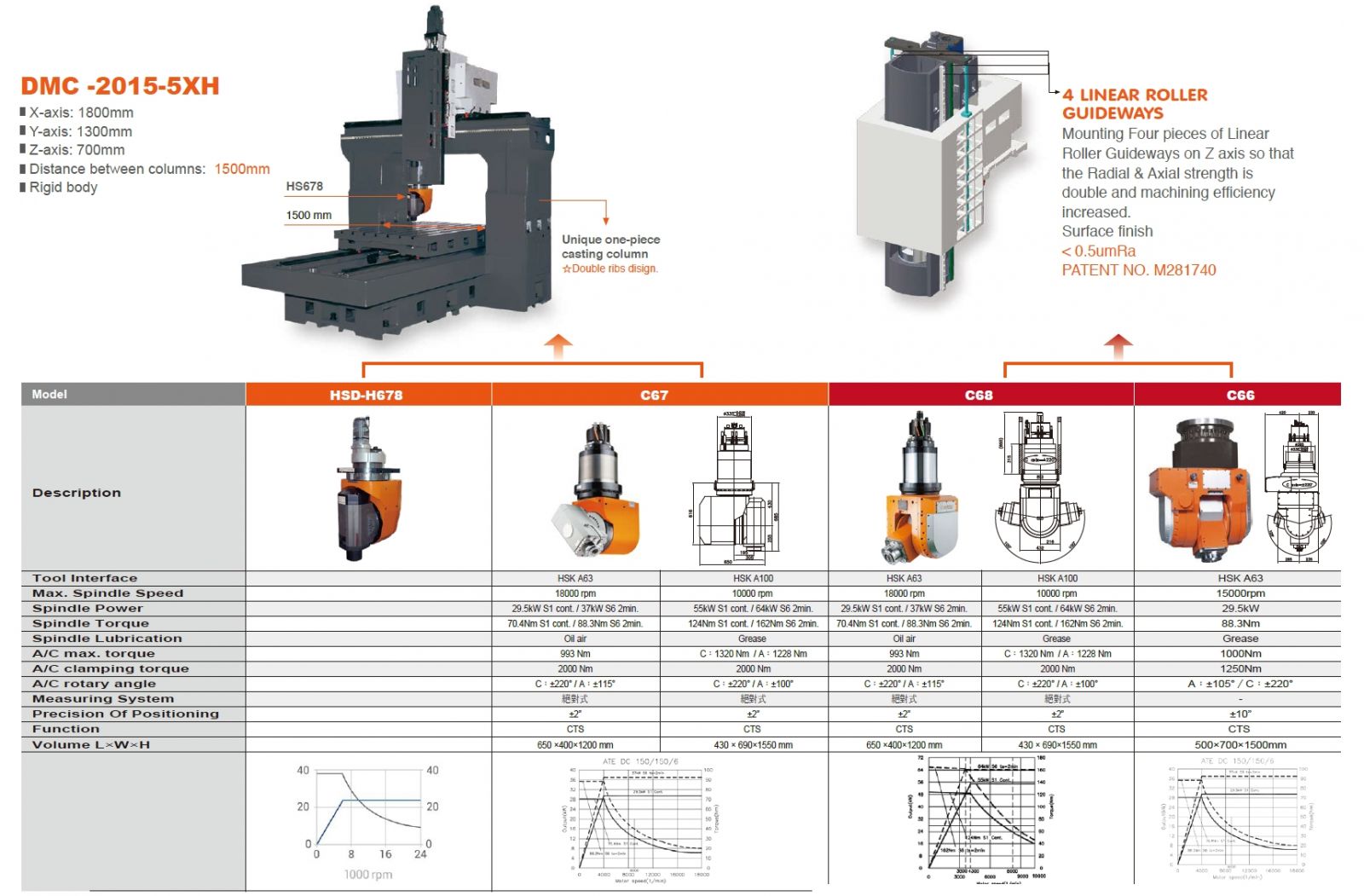

| Spindle | ||

| Spindle speed (Built-in type) | 18000 RPM | rpm |

| Spindle motor (Built-in type) / Torque Max. | 29.5kw / 70.4NM | kw/NM |

| Spindle Taper | HSK A63 | |

| Feedrate | ||

| Cutting feed | 1-10,000 (DEPENGING ON CONTROLLER) | mm |

| X/Y axis rapid traverse(o.p.) | 20 | M |

| Z axis rapid traverse(o.p.) | 12 | M |

|

X axis servo motor

|

HEIDENHAIN :

X, Y axis: QSY-190D 9.6kw 38NM

Z axis: QSY-190C 7.2kw

28NM(+Nitrogen balance)

|

NM |

|

Y/Z axis servo motor

X/Y/Z axis with Gear reducer

|

SIEMENS :

X,Y axis: 1FK7103 5.37kw 36NM

Z axis: 1FK7101 4.87kw 27NM

( +Nitrogen balance)

|

NM |

| Linear guide (Roller Type) | ||

| X axis | X:65x2sets | rpm |

| Y axis | Y:45x2sets + 35x1set | rpm |

| Z axis | Z:55x2sets + 45x2sets | rpm |

| Ballscrew | ||

| X axis ballscrew dia x pitch | 63 x 16 | mm/(in) |

| Y axis ballscrew dia x pitch | 50 x 12 | mm/(in) |

| Z axis ballscrew dia x pitch | 45 x 12 | mm/(in) |

| ATC | ||

|

Type of tool(HSK63A/BT40) Tool capacity

|

12(OP) 16/20 | Armless斗笠式 |

| Type of tool(for BT40/BT50) Tool capacity | 24/30 (Disc type) | Arm刀臂式 |

| Type of tool(for BT40/BT50) Tool capacity | 32/40/60/80/120 (Chain type) | |

| Maximum tool diameter | 24T(BT40) : 78(3.1˝) / 24T(BT50) : 110(4.3˝) | mm/inch |

| Maximum tool length | 24T(BT40) : 300(11.8˝) / 24T(BT50) : 350(13.8˝) | mm/inch |

| Maximum tool weight | 8(17.63) / 20(44) | kgs / lbs |

| Tool to tool time | 1.8 / 2.5 | sec |

| Air supply | 6 | kg / c㎡ |

| Power supply | 45 | KVA |

| Coolant pump | 1HP x 2pcs | HP |

| Machine weight (net) | 36500 / 80300 | kgs / lbs |

| Raiser block 200mm(O.P.) | x | mm |

| Raiser block 500mm(O.P.) | x | mm |